POPULAR WELDING TRAINING

Manufacturers are turning away business due to welder workforce challenges. A structured welding training program helps ensure you are developing and engaging your welder workforce so your business can thrive.

Manufacturers are struggling to find qualified welders. The American Welding Society projects 360,000 welding professionals will be needed by 2027. With more than 155,000 welders approaching retirement, the employment situation is becoming even more urgent.

Successful manufacturers are implementing welding training programs boosting skills for new hires and incumbent employees. This is leading to quicker onboarding, increased productivity and reduced turnover. It’s also building excitement for the next generation of welders as they see the benefits of a career in welding including good pay and rewarding opportunities.

To help streamline welding training, Tooling U-SME has partnered with Lincoln Electric to strengthen the U/LINC® welding Curriculum Platform. Powered by our learning management system, U/LINC promotes learning and student engagement, while giving the instructor maximum control over their programming. Instructors can select a pre-built curriculum or customize their own. U/LINC works with both real welding equipment and Lincoln Electric's VRTEX® Virtual Reality welding simulators, which provide realistic experiences in a safe environment.

Learn more about:

- Quick & Simple to Implement: Welding Training Packages

- Welding Training for Welding Department

- Convenient and Accessible Online Welding Classes

- Personalized Instructor-Led Welding Classes

- Hands-on Experience: Welding Apprenticeships

- Expand & Validate Skills: Welding Certification

- Measure Knowledge: Welding Assessments

- Common Questions About Welding

QUICK & SIMPLE TO IMPLEMENT WELDING TRAINING PACKAGES

A customized welding training approach is essential for manufacturers looking to onboard more quickly, boost productivity and engage employees. It also provides clear pathways for employees to build their welding careers.

We know it’s hard to make training a priority with constant production and customer demands. That’s why we developed training packages to offer quick-start, progressive road maps in welding and other functional areas that allow manufacturers to build career paths for employees. They are intended to enhance your existing on-the-job training and help you create a job progression plan. Unlike many other training programs, these packages require minimal preparation. They are efficient, effective training, developed with input from manufacturing experts.

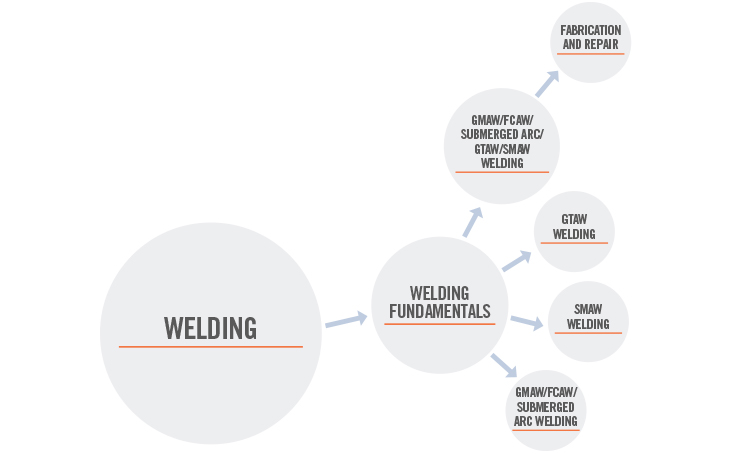

Our virtual welding training offers classes for a variety of welding job roles including:

- Welding Fundamentals

- GMAW/FCAW Submerged Arc/GTAW/SMAW Welding

- Fabrication and Repair

- GTAW Welding

- SMAW Welding

- GMAW/FCAW/Submerged Arc Welding

VIEW WELDING TRAINING PACKAGES

FOR WELDING DEPARTMENTS

- PPE for Welding

- Introduction to Welding

- Electrical Power for Arc Welding

- GTAW Applications

- SMAW Applications

ONLINE WELDING CLASSES

Our online training content is developed with industry experts and designed for all learners. Our classes, including those in the welding area, feature multimedia components to reinforce learning, and pre-and post-tests to measure knowledge gained. Our online classes are self-paced, typically taking 60 minutes to complete. Employees can benefit from all levels of our virtual welding job roles training.

INSTRUCTOR-LED WELDING CLASSES

HANDS-ON EXPERIENCE WELDER APPRENTICESHIPS

Registered apprenticeships are helping manufacturers recruit in-demand employees looking for exciting career opportunities. Established around industry-wide standards, employers can more quickly build a pipeline of skilled workers, boost retention, reduce recruiting costs and improve productivity.

Combining on-the job training (OJT) with related training instruction (RTI) through Tooling U-SME online classes introduces trainees to critical concepts while providing real-world experience — and a paycheck.

Our Apprenticeship Frameworks for welder apprenticeships outline industry-endorsed RTI hours needed to meet the requirements of a competency-based or hybrid apprenticeship program. It provides a predefined welding training curriculum that covers job skills, health and safety, foundations in manufacturing, technical expertise for a welder, and leading and developing people.

WELDING CERTIFICATION

Industry-recognized professional certifications can accelerate movement along a career path in areas such as welding. These earned credentials validate knowledge, skills, and competencies against industry standards.

Welders in a wide variety of industries from aerospace to automotive can use Tooling U-SME’s effective and convenient online training to prepare not only for our own certification exams that build welding knowledge, but other leading industry certification exams as well. This includes those from Manufacturing Skill Standards CouncilNational Institute of Metalworking Skills (NIMS) and SME’s Certified Manufacturing Engineer(CMfgE) and Certified Manufacturing Technologist (CMfgT).

WELDING ASSESSMENTS

Manufacturers can save valuable time and money by delivering onboarding welding training where skills are lacking. Uncovering learning gaps and providing targeted welding training can also help employees at more advanced career stages as well. We can help you evaluate competency strength with 50+ redeveloped assessments including welding assessments. We can also customize welding assessments based on your specific needs.

CONTACT US ABOUT WELDING ASSESSMENTS

COMMON QUESTIONS ABOUT WELDING

What are welding job roles?

There are many different welding career opportunities. Welders touch many of the essential items we use every day from cars to airplanes. The AWS Foundation combines six occupations where welding is a primary job function:

- Boilermakers

- Sheet Metal Workers

- Structural Iron and Steel Workers

- Structured Metal Fabricators and Fitters

- Welding, Soldering, and Brazing Machine Setters, Operators, and Tenders

- Welders, Cutters, Solderers, and Brazers.

Welding professionals understand common welding processes and workpiece materials as well as joint and weld types. From welding fundamentals, skilled welders build more comprehensive and process specific knowledge covering:

- GMAW/FCAW Submerged Arc/GTAW/SMAW Welding

- Fabrication and Repair

- GTAW Welding

- SMAW Welding

- GMAW/FCAW/Submerged Arc Welding

Is there specific training for welding job roles?

Skilled welders are in great demand. Tooling U-SME's classes provide practical and proven training, from basic skills to advanced techniques. At Tooling U-SME, our online welding classes offer greater flexibility with anytime, anywhere access to via smart phones and tablets. Our welding courses cover welding fundamentals, GMAW FCAW Submerged Arc, GTAW, SMAW, and Fabrication and Repair.

What is welding training for?

Welding is an essential part of manufacturing covering industries from aerospace to automotive. A structured welding training program is essential for a successful manufacturing facility. Whether a new hire or mid-career, employees can boost their careers by honing their welding skills.