SMART MANUFACTURING TRAINING

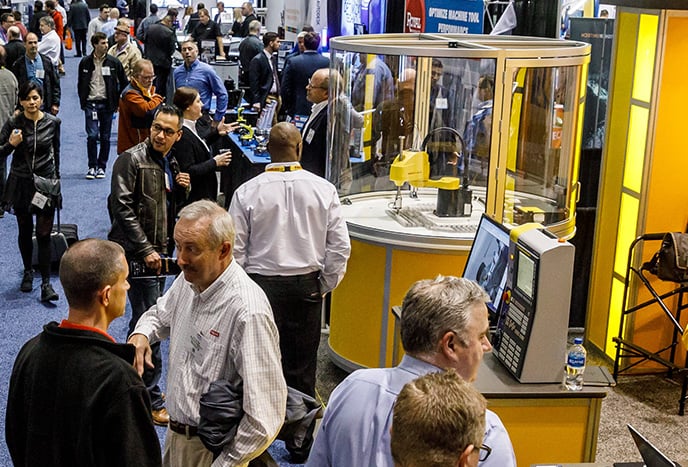

Experts predict the global Smart Manufacturing market will reach nearly $400 billion by 2025. New tech is everywhere, but many manufacturers are struggling with adoption—and upskilling their workforce to maximize their investment. We can help.

Your Smart Manufacturing Training Partner

Our team can design a learning plan to upskill your workforce to prepare for the latest technology and drive awareness.

Accelerate SMART Career Pathways

Create a prepared and motivated workforce with rich, scalable training. From foundational learning to advanced concepts, we offer more than 50 classes that help expedite smart manufacturing adoption, with more in development.

Access the Latest Technology Training

Together with our partners CESMII—the Smart Manufacturing Institute, ARM, and CyManII, we continue to develop educational resources that remain current with rapidly changing technology and focus on democratizing access to training to build smart manufacturing skills.

Smart Manufacturing Training

WHAT IS SMART MANUFACTURING? STANDARDIZATION THROUGH COLLABORATION

In Smart Manufacturing, resources and processes are integrated, monitored, and continuously evaluated with the sensing, information, process modeling,

In Smart Manufacturing, organizations, people, and technology work in synergy via processes and technology-based solutions that are secure, scalable, flat and real-time, open and interoperable, proactive and semi-autonomous, orchestrated and resilient, and sustainable.

The Role of Robotics

Robotics is revolutionizing Smart Manufacturing by automating tasks, increasing efficiency, and improving product quality. Collaborative robots (cobots) are working alongside humans, creating a safer and more flexible work environment. The integration of robotics is crucial for businesses to stay competitive in today's global market.

Learn More

VIRTUAL LABS FOR MANUFACTURING

We have launched a new, immersive training curriculum designed to bridge the gap between learning and doing that uses Virtual Reality to provide realistic training experiences.

VIRTUAL REALITY

Additive Manufacturing

The additive manufacturing industry is rapidly growing, increasing demand for skilled professionals and spurring advancements in technology. Key trends include automation, AI, and sustainability. Additive manufacturing offers benefits like customization, waste reduction, and design flexibility, making it a revolutionary force in various sectors.

Learn More

OUR CAPABILITIES

The Smart Manufacturing revolution is transformational, improving speed, agility, quality, throughput, safety, efficiency, and productivity. And we’d like to help you to get there. Now.

LEARN MORE

BLOGS, EVENTS, WEBINARS AND MORE

Wherever you are on your Smart journey, we've got you covered. Whether you are just starting out or are fully immersed in a Smart Factory, we have the resources to help you advance.

BROWSE RESOURCES

Smart Manufacturing Magazine

SME’s Smart Manufacturing Magazine focuses on advanced manufacturing technologies and tools that are driven or enhanced by integrated information technology. Get your subscription.

SUBSCRIBEA SMART MANUFACTURING ROADMAP FOR SMALL AND MEDIUM-SIZED MANUFACTURERS

Smart Manufacturing Partners

Smart Manufacturing Contact Us

SMART MANUFACTURING VOCABULARY

Do you know Smart Manufacturing? Below are 40 common Smart Manufacturing terms. How many are new to you?

3D printing—The process of producing a 3D object using a specialized tool that creates successive layers of material. 3D printing must technically involve the use of a print head or nozzle, but the term is often used interchangeably with additive manufacturing (AM).

Additive Manufacturing —AM. The process of successively layering materials to make an object based on a three-dimensional (3D) computer model. Additive manufacturing allows for rapid prototyping, mass customization, and increased part complexity.

Algorithms—A mathematical process designed to systematically solve a problem. Complex digital algorithms allow machine learning to predict and regulate operations.

Augmented Reality—AR. A technology that superimposes a computer-generated image on a view of the real world. Augmented reality methods maybe be used with smart safety goggles to visually alert the wearer to potential hazards.

Big Data—A valuable collection of information from the devices or assets in an operation. Big Data can be analyzed to reveal patterns and make calculations.

Blockchain—A growing list of digital records, called blocks, that are linked. Blockchain technology is a decentralized, distributed ledger that records the origin of a digital asset.

Collaborative Robotics—A subset of robotics that focuses on enabling robots to work closely with human operators. Collaborative robotics is often a cost-effective alternative to traditional automation.

Computer-Aided Design —CAD. Computer software used to create a digital model of a part before it goes into prototyping or production. Computer-aided design models are converted to an STL format for use by additive manufacturing (AM) machines.

Computer-Aided Manufacturing—CAM. The use of computer software that facilitates the development of part programs to produce a part. Computer-aided manufacturing software applications create an image of the workpiece and develop the program code from information that the programmer inputs.

Cyber-Physical System—Cyber-physical system or CPS. A hardware device that links physical objects and processes with virtual objects and processes in an interconnected network. A CPS increases the capabilities of a device.

Deep Learning—An advanced form of machine learning that uses neural networks with multiple hidden layers. Deep learning algorithms can enable machines to exhibit advanced, human-like behaviors but require significant amounts of data.

Design for Manufacturing—DFM. The methodology of planning, testing, and creating a part that functions correctly and is easy to manufacture. Design for manufacturing, also known as design for manufacturability, involves considering part functionality and the limits of the manufacturing process.

Digital Supply Chain—DSC. A web-based network of computers, companies, and systems that exchange resources to deliver products to customers. A digital supply chain connects suppliers and stakeholders throughout the entire product lifecycle.

Digital Thread—An integrated view of all the data and information about a part or product throughout its lifecycle. The digital thread connects information from all aspects of a product into one seamless network.

Digital Twin—A virtual representation of a physical object, such as a part or machine. A digital twin evolves with the object throughout its lifecycle.

Edge Computing—The practice of using software and storing data on multiple local devices located at the data source. Edge computing distributes processing tasks across multiple edge devices at the data source.

Edge Detection—An image processing technique that identifies the boundaries of objects in images. Edge detection assists machines in better handling parts.

Edge Devices—A computing device that processes data near the source that created it. Edge devices may include routers, gateways, and smart devices that process data.

End Effector—A device attached to the end of the robot arm in order to interact with a part, component, or material. The end effector, also known as an end-of-arm tool (EOAT), may be a gripper that allows the robot to pick up objects and place them down, or it may be a welding torch or tool, such as a grinder, that performs a manufacturing task.

Evil Twin Attack—The process of tricking a wireless internet user into connecting to a rogue AP set up by a hacker. Evil twin attacks often occur on open wireless local area networks.

Extended Reality—Extended reality, or XR, includes mixed, virtual, and augmented reality, which are technologies used to enhance or simulate real-world environments and provide more information or create an artificial experience.

Gateway—A device used to join two incompatible hardware components or protocols on a network. Gateway devices are available as preconfigured or configurable.

Geofence—A virtual geographic boundary that triggers a response when a person with wearable technology or a smart device enters or leaves an area. A geofence can be used to monitor safety.

Geolocation—Identifies the real-world geographic location of a person or object. Geolocation trackers make it possible to monitor the position of inventory in real time.

Human-Machine Interface—HMI. A device connected to the control system that allows personnel to monitor and control a machine or process. A human-machine interface can vary widely in size or complexity based what is being controlled.

Image Sensor—A device that detects the light gathered from a lens and converts it into an electrical signal. Image sensors collect the object's shape and surface information as pixels.

Industrial Internet of Things—IIoT. A network of physical devices used in manufacturing that contain computing systems that allow them to send and receive data. The Industrial Internet of Things allows devices to exchange data and automate processes without any human intervention.

Industry 4.0—A stage in manufacturing that uses connected devices and digital technologies. Industry 4.0 uses automation and data exchange to achieve advancements in a variety of industries.

Internet of Things—IoT. A network of devices that contain sensors that allow them to send and receive data. The Internet of Things is the network on which devices other than computers exchange data.

MTConnect—A communication standard that works as a universal translator between computer software and thousands of different machine and device languages. MTConnect is open source and can be easily modified or adapted to a specific task.

Object Recognition—The ability of an artificial intelligence system to identify specific objects using machine learning algorithms. Object recognition is considered a computer vision capability.

Programmable Logic Controllers—PLCs. A processor-driven device that uses logic-based software to provide electrical control to a machine or process. Programmable logic controllers are used in factory automation.

Qualitative Data—Measuring the descriptive characteristics of a thing such as height, weight, or gender. Qualitative typically describes any non-numeric data.

Quantitative Data—Measuring an amount or number. Quantitative data typically includes anything that can be counted or measured numerically.

Radio-Frequency Identification—RFID. A technology that uses electromagnetic fields to automatically identify and track tags attached to objects. Radio-frequency identification requires a scanner and a tag.

SAP—A type of software that acts as a framework, translator, and interface between different individual operational software package languages. SAP stands for systems, applications, and products in data management.

Smart Manufacturing—Smart Manufacturing is the information-driven, event-driven, efficient and collaborative orchestration of business, physical and digital processes within plants, factories, and across the entire value chain. In Smart Manufacturing, resources and processes are integrated, monitored, and continuously evaluated with the sensing, information, process modeling, predictive analytics, and workflow needed to automate routine actions, and prescribe action for non-routine situations.

Smart Sensor—A device equipped with software that can detect physical inputs, process them as data, and output digital signals. Smart sensors are more advanced than normal digital sensors since they can process data internally rather than simply sending digital signals to an external system to be processed.

Supervised Machine Learning—A process in which a human operator labels data inputs for a machine learning model and defines the desired outputs the model should produce. Supervised machine learning typically requires extensive human labor in order to prepare and label data sets.

Turing Test—A test designed by Alan Turing that could theoretically be used to rate the intelligence of a computer. The Turing Test essentially rated a computer's responses to text-based questions on whether the computer's response could be differentiated from a human's response.

Virtual Reality—Virtual reality, or VR, is a computer-generated simulation of a three-dimensional environment that may be interacted with using specialized electronic equipment, such as a headset and hand controls.