POPULAR MAINTENANCE TRAINING

Skilled maintenance technicians remain in demand. A structured maintenance training program is essential for manufacturers looking to improve safety and productivity while reducing facility costs.

According to the Bureau of Labor Statistics, overall employment of industrial machinery mechanics, machinery maintenance workers, and millwrights is projected to grow 14 percent from 2021 to 2031, much faster than the average for all occupations.

Baby boomer retirements are leading to more maintenance and automation job openings. In addition, as companies move to Smart Manufacturing, changing technologies are adding complexity to equipment repair, often requiring more in-depth maintenance training.

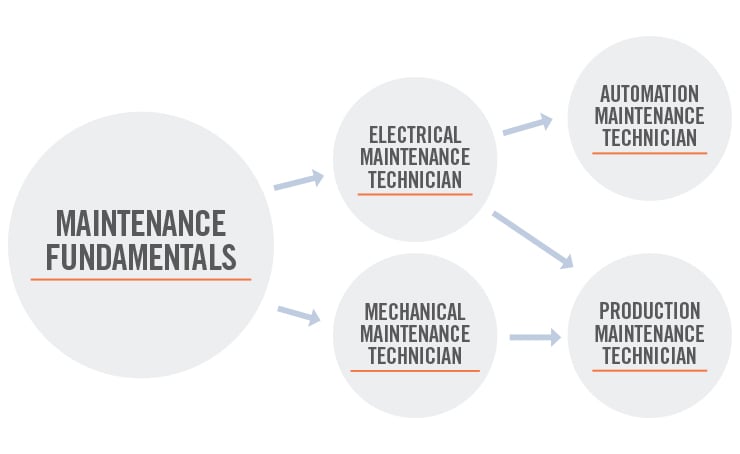

The challenge is finding enough skilled technicians to fill openings for a variety of maintenance job roles including:

- Maintenance Fundamentals: Introduces common manufacturing maintenance competencies, including safety, mathematics used in manufacturing, electrical and mechanical systems, inspection, rigging, Quality & Lean, and Industry 4.0.

- Electrical Maintenance Technician: Responsible for the general upkeep of electrical system. Conducts routine maintenance, perform repairs, and fix faulty wiring when necessary. May also be required to replace electrical components.

- Automation Maintenance Technician: Maintains and repairs robots or peripheral equipment, such as replacement of defective circuit boards, sensors, controllers, encoders, PLCs or end-of-arm tools or conveyors.

- Mechanical Maintenance Technician: Responsible for maintaining, troubleshooting, and repairing manufacturing equipment. May be required to install, troubleshoot, and maintain mechanical devices, remove defective parts and make repairs.

- Production Maintenance Technician: Performs preventive maintenance and skilled repairs on complex electrical and mechanical production equipment and systems, sensor or feedback systems, hydraulics, or pneumatics.

These maintenance job roles are essential as most manufacturers realize the critical nature of a well-executed maintenance program to remain competitive. A successful preventive maintenance program can help a facility reduce equipment downtime, promote longer machine life, improve safety and increase productivity. All of this helps reduce costs.

To meet the demand, manufacturers need to identify new and incumbent employees who can grow in open maintenance job roles. Our online maintenance classes, instructor-led classes, maintenance apprenticeships, certifications, and assessments can ensure you have the talent you need. Employees will appreciate the clear career pathways offering good-paying career opportunities.

Learn more about:

- Quick & Simple to Implement Maintenance Training Packages

- Maintenance Content Training for Maintenance Department

- Convenient and Accessible Online Maintenance Classes

- Personalized Instructor-Led Maintenance Classes

- Hands-on Experience: Maintenance Apprenticeships

- Expand & Validate Skills: Maintenance Certification

- Measure Knowledge: Maintenance Assessments

- Common Questions About Maintenance

QUICK & SIMPLE TO IMPLEMENT MAINTENANCE TRAINING PACKAGES

Maintenance training helps ensure that up-and-coming and incumbent technicians have the skills they need to create and administer a preventive and responsive maintenance program that reduces downtime, lessens the need for costly repairs, and increases productivity. It also provides clear pathways for employees to build their careers.

With constant production and customer demands, we know it’s hard to make training a priority. That’s why we developed training packages to offer quick-start, progressive road maps in maintenance and other functional areas that allow manufacturers to build career paths for employees. They are intended to enhance your existing on-the-job training and help you create a job progression plan. Unlike many other training programs, these packages require minimal preparation. They are efficient, effective training, developed with input from manufacturing experts.

Our virtual maintenance training offers classes that cover maintenance fundamentals, electrical production, maintenance production, and training for a variety of maintenance job roles:

- Electrical Maintenance Technician

- Automation Maintenance Technician

- Mechanical Maintenance Technician

- Production Maintenance Technician

TRAINING FOR MAINTENANCE DEPARTMENTS

We have nearly 600 unique online courses, and instructor-led training titles plus custom courses, providing an incredibly broad catalog of manufacturing training topics. From onboarding classes for maintenance to more advanced maintenance job roles training, Tooling U-SME offers a wide range of courses to develop a skilled team including classes in:

ONLINE MAINTENANCE CLASSES

Our online training content is developed with industry experts and designed for all learners. Our classes, including those in the maintenance area, feature multimedia components to reinforce learning, and pre-and post-tests to measure knowledge gained. Our online classes are self-paced, typically taking 60 minutes to complete. Employees can benefit from all levels of our virtual maintenance job roles training.

INSTRUCTOR-LED CLASSES

Employees can learn onsite at your facility, at an offsite location, or virtually. Led by experts, instruction is engaging and interactive, and can include hands- on equipment training. Instructors cover a wide variety of topics to enhance maintenance and automation training such as Basic Electrical Concepts, Motor Theory, High Voltage Switchgear, Hand and Power Tools, and Digital Circuits.

HANDS-ON EXPERIENCE MAINTENANCE APPRENTICESHIPS

Registered apprenticeships are helping manufacturers recruit in-demand employees looking for exciting career opportunities. Established around industry-wide standards, employers can more quickly build a pipeline of skilled workers, boost retention, reduce recruiting costs and improve productivity.

Combining on-the job training (OJT) with related training instruction (RTI) through Tooling U-SME online classes introduces trainees to critical concepts while providing real-world experience — and a paycheck.

Our Apprenticeship Frameworks for Maintenance Technician, Mechatronics Technician and Electrical Technician apprenticeships outline industry-endorsed RTI hours needed to meet the requirements of a competency-based or hybrid apprenticeship program. It provides a predefined maintenance training curriculum that covers job skills, health and safety, foundations in manufacturing, technical expertise for a maintenance technician/mechatronics technician/electrical technician, and leading and developing people.

MAINTENANCE CERTIFICATION PREP

Industry-recognized professional certifications can accelerate movement along a career path in areas such as maintenance. These earned credentials validate knowledge, skills, and competencies against industry standards.

Maintenance and Automation Technicians and others can use Tooling U-SME’s effective and convenient online training to prepare not only for our own certification exams that build machining knowledge, but other leading industry certification exams as well. This includes those from Manufacturing Skill Standards Council (MSSC), National Institute of Metalworking Skills (NIMS) and SME’s Certified Manufacturing Associate (CMfgA), Certified Additive Manufacturing – Fundamentals (CAM-F), Robotics in Manufacturing Fundamentals (RMF) and Lean Certification.

ONLINE MAINTENANCE CLASSES

Manufacturers can save valuable time and money by delivering onboarding maintenance training where skills are lacking. Uncovering learning gaps and providing targeted maintenance training can also help employees at more advanced career stages as well. We can help you evaluate competency strength with 50+ redeveloped assessments including maintenance assessments. We can also customize maintenance assessments based on your specific needs.

MAINTENANCE TRAINING & CAREER PATHWAY SUPPORT

COMMON QUESTIONS ABOUT MAINTENANCE

There are a variety of maintenance job roles including Electrical Maintenance Technician, Automation Maintenance Technician, Mechanical Maintenance Technician and Production Maintenance Technician.

These maintenance professionals perform varied and essential tasks at a manufacturing facility. They are responsible for performing both preventative and predictive equipment maintenance. Maintenance technicians troubleshoot electrical, hydraulic, pneumatic and mechanical system issues. They also set up and operate tools to make and repair parts. Maintenance professionals provide valuable input into how to improve operations, quality and safety.

Is there specific training for maintenance job roles?

Skilled maintenance technicians are in great demand. Tooling U-SME's classes provide practical and proven training, from basic skills to advanced techniques. At Tooling U-SME, our online maintenance classes offer greater flexibility with anytime, anywhere access to via smart phones and tablets. Our maintenance courses cover maintenance fundamentals, electrical maintenance technician skills, automation maintenance technician skills, mechanical maintenance technician skills and production maintenance technician skills.

What is maintenance training for?

A structured maintenance program is essential for a successful manufacturing facility. Maintenance professionals are needed to ensure the right equipment is in place and running smoothly on a daily basis. Whether a new hire or mid-career, employees can boost their careers by honing their skills in the maintenance area.