POPULAR MACHINING TRAINING

Machinists are in high demand. A structured machining training program covering various machining job roles, will help you develop a skilled team that delivers greater productivity, efficiency, and quality.

Free Trial

The Bureau of Labor Statistics projects that there will be more than 41,000 openings for manual and computer numerical control (CNC) machinists and tool and die makers each year through 2031. Now is the time for manufacturers to identify new and incumbent employees who can grow in open machinist job roles.

The industry needs the precision, creativity, and problem-solving abilities of machinists for continued growth. Our online machining classes, instructor-led classes, machining apprenticeships, certifications, and assessments, can ensure you have the talent you need while offering your employees good-paying career opportunities.

Learn more about:

- Build Career Pathways Training: Machining Job Roles

- Quick & Simple to Implement Machining Training Packages

- Convenient and Accessible Machining Classes

- Machining Content Training for Machining Department

- Personalized Instruction Instructor-Led Classes

- Hands-on Experience: Machining Apprenticeships

- Expand & Validate Skills: Certification

- Measure Knowledge: Machining Assessments

- Common Questions About Machining

BUILD CAREER PATHWAYS TRAINING: MACHINING JOB ROLES

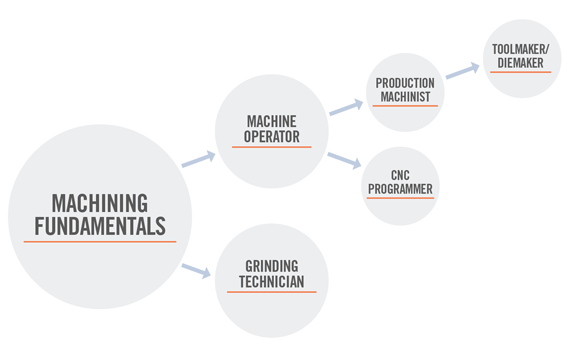

The manufacturing industry is actively recruiting and developing machinists in a variety of job roles. We help manufacturers build curriculums covering everything from onboarding machining classes to more advanced online CNC machining courses. This training builds competencies in job roles including:

Machine Operator: Monitors machine operation and quality, sets up equipment, responsible for preventive maintenance and troubleshooting.

Grinding Technician: Sets up and operates equipment to perform precision grinding based on specifications.

CNC Programmer: Reads blueprints, programs CNC machine, monitors machine operation and quality.

Production Machinist: More senior role requiring additional training to program and repair machines, inspect parts for quality and troubleshoot.

Toolmaker/Diemaker: Type of machinist that reads blueprints, creates designs with CAD software, operates CNC machines, and monitors quality.

QUICK & SIMPLE TO IMPLEMENT MACHINING TRAINING PACKAGES

It’s hard to make training a priority when you have the pressures of production and high customer expectations. That’s why we developed training packages around specific topics to quickly get your employee development program up and running. Our manual and CNC machining training packages target specific business needs whether building the competency and efficiency of new hires in minimal time or upskilling the incumbent workforce to optimize new and advanced technologies and processes.

Innovation comes through familiarity and expertise. Ensure your machinists are skilled in programming, setting up, operating, and maintaining your equipment. This allows them to more accurately troubleshoot, making important adjustments for efficiency and productivity. You’ll see the impact of machining training packages on your bottom line.

MACHINING CLASSES

- Abrasives

- CNC Machining

- CNC Controls: Fanuc

- CNC Controls: Haas

- CNC Controls: Mazak

- Manual Machining

- Metal Cutting

- NIMS

- Workholding

Our content is developed with industry experts and designed for all learners. Our classes, including those for manual and CNC machining, feature multimedia components to reinforce learning, and pre-and post-tests to measure knowledge gained. Employees can benefit from all levels of our machining job roles training.

VIEW CATALOG

INSTRUCTOR-LED CLASSES

Employees can learn onsite at your facility, at an offsite location, or virtually. Led by experts, instruction is engaging and interactive, and can include hands-on equipment training. Instructors cover a wide variety of topics to enhance machining training such as CNC Machining Fundamentals and Basic Electronics.

Contact us today to discuss a customed machining curriculum

View Maching ILT Classes

HANDS-ON EXPERIENCE MACHINING APPRENTICESHIPS

Registered apprenticeships are successfully addressing the critical manufacturing skills gap.

Established around industry-wide standards, employers can more quickly build a pipeline of skilled workers, boost retention, reduce recruiting costs and improve productivity.

Combining on-the job training (OJT) with related training instruction (RTI) through Tooling U-SME online classes introduces trainees to critical concepts while providing real-world experience — and a paycheck.

Our Apprenticeship Framework for a CNC Machinist apprenticeship outlines industry-endorsed RTI hours needed to meet the requirements of a competency-based or hybrid apprenticeship program. It provides a predefined CNC machining training curriculum that covers job skills, health and safety, foundations in manufacturing, technical expertise for a CNC machinist, and leading and developing people.

LEARN MORE

CERTIFICATION

Industry-recognized professional certifications can boost careers in machining. These earned credentials validate knowledge, skills, and competencies against industry standards. Machine operators and others can use Tooling U-SME’s effective and convenient online training to prepare not only for our own certification exams that build machining knowledge, but other leading industry certification exams as well. This includes those from Manufacturing Skill Standards Council (MSSC), National Institute of Metalworking Skills (NIMS) and SME’s Certified Manufacturing Associate (CMfgA) and Lean Certification.

LEARN MORE

MACHINING ASSESSMENTS

Manufacturers can save valuable time and money by delivering onboarding machining training where skills are lacking. Uncovering learning gaps and providing targeted manual and CNC machining training can also help employees at more advanced career stages as well. We can help you evaluate competency strength with 50+ redeveloped assessments including machining assessments. We can also customize machining assessments based on your specific needs.

For Machining Training & Career Pathway Support:

CONTACT US

COMMON QUESTIONS ABOUT MACHINING

What is machining?

Machining is used to manufacturer precise tools and parts. Machinists are building a better world. Machined parts include everything from critical components for aerospace to life-saving surgical instruments to specialized parts for the latest car model.

What is a CNC machinist?

There are two types of machining: manual and CNC. CNC is an automated manufacturing process controlled by a computer. A CNC machinist operates and programs tools that cut, shape, and grind metal for specific parts.

What is machining operator training for?

Whether a new hire or mid-career, employees can boost their careers by honing their machining skills. Machining training covers foundational through advanced topics. Machining classes include CNC, manual machining, laser cutting, water jet cutting and other critical functions.

At Tooling U-SME, our online machining classes for greater flexibility with anytime, anywhere access to via smart phones and tablets.

Is there specific training for CNC machinists?

Skilled CNC machinists are in great demand. With an emphasis on CNC machining and turning centers, Tooling U-SME's classes provide practical and proven training, from basic skills to advanced techniques, including programming, on a variety of brands and machines.