Be a Blog Subscriber

Join thousands of manufacturing leaders and professionals who get the Accelerate blog delivered straight to their inbox

They call themselves “Diné Bizaad,” or “The People.” They’ve done so for millennia, long before Spanish explorers began invading their tribal lands in the Four Corners region of what is now the southwestern United States. Persevering through the warfare, slavery and broken promises that followed, the Navajo remain a proud nation for whom self-reliance, what they call “t’áá hwó’ ají t’éego,” is to be valued.

And yet, even the most self-reliant of us need to adapt and learn new skills to be successful. We also need opportunities. Both have long been in short supply on tribal lands. Speaking before the United States Commission on Civil Rights, Jonathan Nez, president of the Navajo Nation, explained that 40% of homes there lack running water and internet service, cellular access is scarce and even basic infrastructure ranges from poor to nonexistent.

According to public census data, Nez is responsible for the largest American Indian reservation in the U.S., comprising more than 22,500 square miles (5,8275 sqm) that extends into Arizona, New Mexico and Utah. An estimated 140,400 Navajo tribal members live within reservation boundaries, while another 160,000 live outside the reservation. The median age is 34, with about 39% of the population under 19. The per capita and median household income are just $16,698 and $33,578 respectively, putting 35.5% of the population below the poverty line.

Most alarming to Scott Halliday is that less than 10% of Navajo people have a bachelor’s degree or higher, a sad statistic he’s trying to change. “We’ve had snow the past couple of days, so the roads are frozen, but as soon as it warms up, everything will turn to mud and they won’t be able to leave their homes,” he noted during an early February phone interview. “So we might not see them tomorrow or even next week, but eventually, they’ll come—given the chance, they always finish what they started.”

The “they” he’s referring to are the students of Navajo Technical University (NTU) in Crownpoint, N.M. Chartered in 1979 as the Navajo Skill Center, the school became a land grant university in 1994 and now is the largest tribal college in the U.S. It offers a variety of associate’s and bachelor’s programs—including an engineering technology degree—as well as masters’ programs in electrical engineering and management information systems, with a total enrollment of about 1,800. STEM and advanced manufacturing are key focuses.

Halliday, who has been teaching at NTU since 2003, is the director of the school’s Center for Advanced Manufacturing (CAM). Opened in 2020 out of a $3.5 million grant from the National Science Foundation, CAM provides valuable learning tools and experience to undergraduate and graduate students, as well as visiting researchers. It also supports economic development for the overall community.

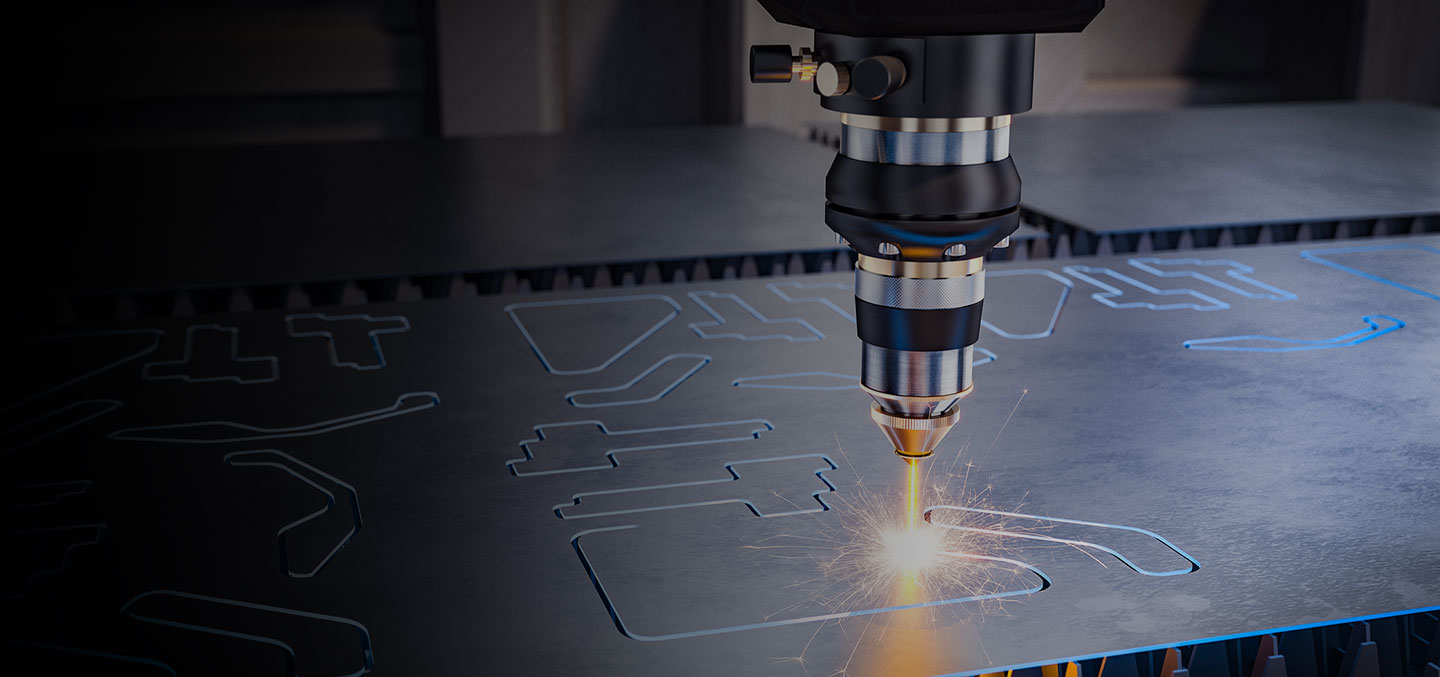

Halliday describes CAM as a metal additive manufacturing (AM) research lab—and a robust one at that. At the top of its capabilities list is a hybrid directed-energy deposition (DED) 3D printer from Optomec, followed by an assortment of CNC machine tools and auxiliary equipment. Students learn how to apply build parameters, prepare CAD files, set up a machine and make parts. When done, they’ll perform the necessary post-processing steps, from heat treatment and CNC machining to final inspection on a coordinate-measuring machine, powder analysis and mechanical testing, plus characterization microscopy.

“We cover the entire additive gamut, as well as the fundamentals of manufacturing,” Halliday says. “For this, we rely heavily on materials from Tooling U-SME, which plays a key role in providing educational and workforce development support and will be incorporated in NTU’s apprentice-style training for students.”

The Tooling U-SME courses apply to what the center is trying to accomplish. Topics range from general shop safety, metrology and CNC programming to material science and additive manufacturing. There are also several National Science Foundation, Department of Defense and National Nuclear Security Agency grants that have been awarded to NTU to develop CAM and help grow NTU’s engineering programs. To this end, more than 40 students have earned engineering- and manufacturing-related degrees since 2020.

The facility sits in the heart of ancestral lands defined by four sacred mountains—Blanca Peak and the La Plata Mountains in Colorado, Arizona’s San Francisco Peaks and nearby Mount Taylor. Young people in the area are encouraged to explore and gain knowledge, then return to share what they’ve learned.

“The Navajo possess a great sense of self and community, and how these fit into the larger world,” Halliday says. “And while they typically want to remain on the reservation after graduating, there’s no industry on Navajo lands. So even though most of them have an entrepreneurial spirit, there’s very little opportunity to pursue that, let alone earn a decent living.”

While a few stay on as interns after graduation, most of Halliday’s students must leave their homeland to earn a living. Some have gone to work at Intel in Portland, while others have found employment at the Air Force Research Lab National Laboratory (LLNL) in Rome, N.Y., and the Army Research Lab in Huntsville, Ala. Thanks to CAM along with significant interest from research and development organizations such as Sandia National Laboratory and the Department of Energy’s Los Alamos National Laboratory (LANL), however, the paradigm is beginning to shift.

“Most of CAM’s engineering faculty and I have grants from these and other institutions that fund student internships,” Halliday explains. “That makes us an industry partner able to work on a wide range of external projects. For instance, LANL has hired six of our graduates to help develop fuel cell technology here in our lab. We’re also talking to them and Sandia about creating a satellite facility nearby so that interns can do contract work, while also making it easier for their scientists to visit and interact with our staff and students.” This isn’t just a corporate jobs program. Partners benefit from CAM’s advanced research. The center has developed instrumentation for acoustic emissions used to detect any cracking that might occur during the 3D-printing process.

The center also conducts thermal imaging of the melt pool with a commercial monitoring system it developed. Here, an infrared camera is used to analyze heat signatures of the part and surrounding areas. Researchers CT scan the completed part and compare the in-situ measurements to look for anomalies or defects.

Industry partners such as SME, government institutes and local manufacturing companies are critical to CAM’s future success. To this end, the university is looking to broaden its relationship and list of prospective employers.

“NTU is working on building the infrastructure needed to attract companies looking to diversify their manufacturing base within the U.S.,” Halliday says. “NTU and the Navajo Nation want to participate in the ‘new’ manufacturing economy, not just participate in the ‘hand-me-down’ manufacturing economy that is left behind. We’ve made excellent progress in becoming a vendor/contractor for Sandia National Laboratories and Los Alamos National Laboratories—as the Center continues to expand its capabilities and demonstrate a strong track record, it is expected that more companies will seek out NTU and the Navajo Nation.

It’s all about creating industry in Navajo Nation and broadening opportunities for its people.

Join thousands of manufacturing leaders and professionals who get the Accelerate blog delivered straight to their inbox