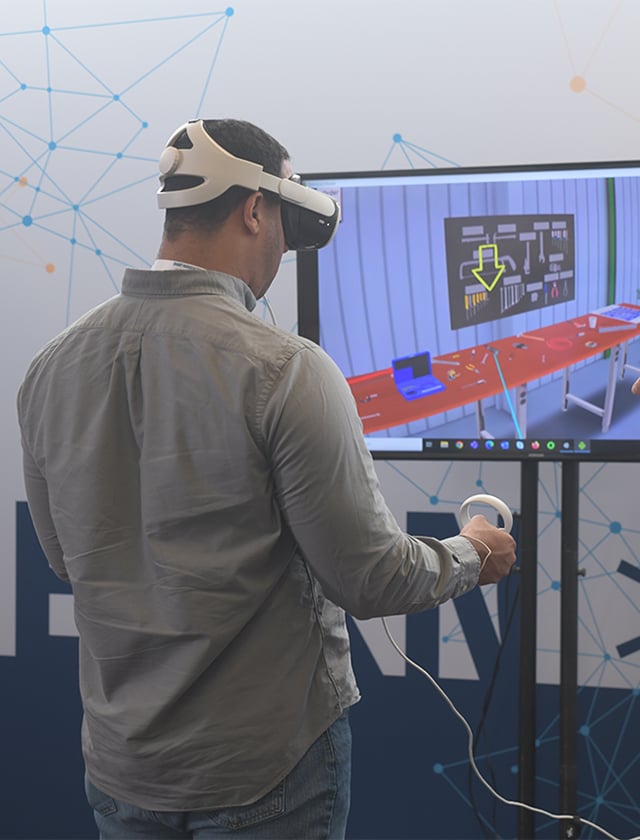

APPLIED LEARNING THROUGH VIRTUAL REALITY

Just as the manufacturing industry is embracing technology to move better and faster into the future, we can optimize training by leveraging technology. Our new Virtual Labs provide an immersive virtual reality training curriculum, with eLearning prerequisites and Skills Guides that support OJT, to bridge the gap between learning and doing.

GAIN REAL-WORLD EXPERIENCE IN A CONTROLLED ENVIRONMENT

Our Virtual Labs packages provide a structured way to set up and integrate Virtual Reality into your training program and support the blended learning approach of Learn. Practice. Perform.

- Learn new information through standard instruction

- Practice skills in a safe, virtual environment

- Perform tasks and apply knowledge on the job or in the classroom

Benefits of Virtual Learning

By providing realistic, immersive experiences for learners to work with simulated equipment, Tooling U-SME Virtual Labs accelerate competency for real-world manufacturing situations.

Increase Retention

Based on the concept of Learn-Practice-Perform, the Virtual Labs are an efficient way to safely build knowledge that contributes to confidence and proficiency.

Enhance productivity

Virtual Labs help manufacturers and educators engage, onboard, and upskill learners to build a high-performing, advanced manufacturing workforce.

Increase safety

Virtual Labs allow for repeated practice in a safe environment after students or employees gain a baseline knowledge through their eLearning curriculum and before training on real equipment.

Lower costs

Virtual Labs optimize training and its effectiveness and scalability through leveraging technology.

Engage a multi-generational workforce

Virtual Labs resonate for learners of all ages and experience levels. Younger users enjoy donning the Meta Quest 2 headset and entering a virtual world and seasoned employees are engaged through new learning delivery methods.

VR Training eBook

Virtual reality (VR) workforce training combats this by helping companies and educators engage, onboard, upskill learners to build a high-performing, advanced manufacturing workforce and strengthen the industry’s competitiveness. As technology improves and costs decrease, virtual reality training has become scalable and accessible.

Manufacturers are seeing beneficial results such as:

- Lowered Costs

- Improved Safety

- Increased Productivity

- Boosted Retention

- Increased Engagement

- Accelerated Time to Competency

- Improved Ability to Attract the Next Generation Workforce

- Deeper engagement of the Incumbent Workforce

Read the eBook to learn more about the benefits of using virtual reality manufacturing training, implementation costs, how to get started, and more.

Read the Book

Applied Learning Model Accelerates Training

Read this case study and learn how an automotive parts supplier to original equipment manufacturers utilized virtual reality training to overcome talent challenges and increase the number of trained associates available to perform repair welding functions.

Read the Case Study